How to Recycle Plastics?

What is Plastic?

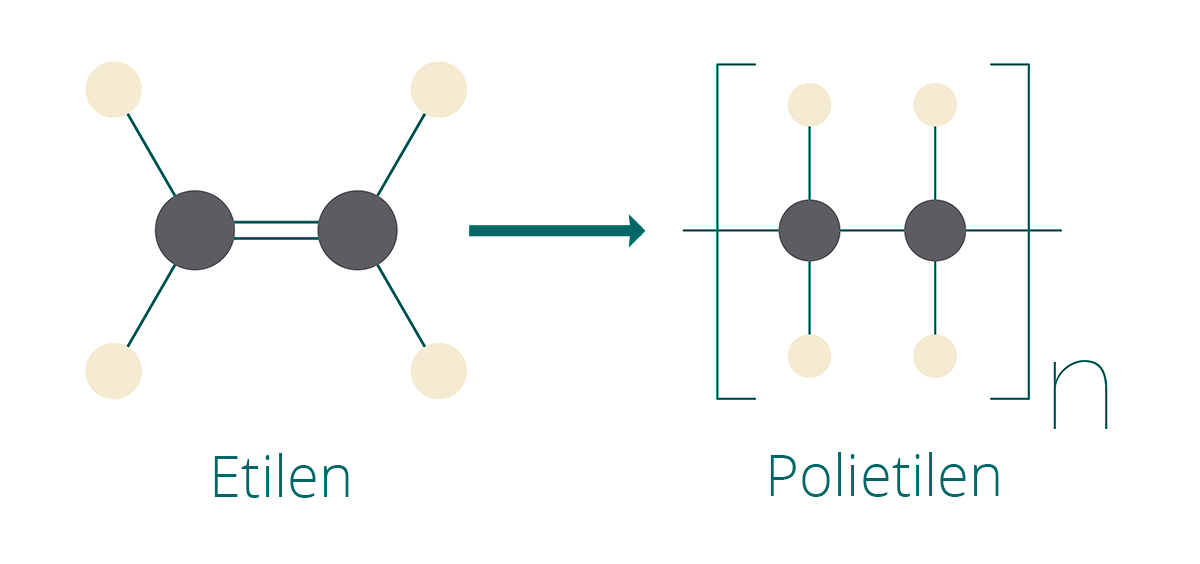

Plastics are materials formed by the interconnection of small molecular units consisting of elements such as carbon, oxygen and hydrogen. These molecular units that make up the plastic are called monomers. For example, the ethylene (C )2H4) molecule is a monomer. Plastics can be shaped under temperature and pressure.

How is Plastic Produced?

Plastics are produced katalizörler This long, chain-like structure is called a polymer. This method used in plastic production is called polymerization. For example, polyethylene is a type of plastic.2H4In the presence of a catalyst, the double bonds between the carbons in the ethylene (C ) molecule are broken. Then, more than one ethylene molecule is connected to each other and a chain-shaped structure is obtained.

In everyday life, we use plastics with different chemical structures. For example, polyethylene terephthalate (PET) in disposable water bottles, ethylene glycol (C2H6O2) and terephthalic acid (C8H6O4), while polyethylene (PE) used in the insulating layers outside the cables is composed of multiple ethylene (C2H4) molecules together. Polypropylene (PP) used in cleaning sponges, polyvinyl chloride (PVC) used in doors and windows, polystyrene (PS) used to make foam materials and polyamide (PA) used to make nylon fabric are also different types of plastics.

Polystyrene is a type of plastic used to make foam materials.

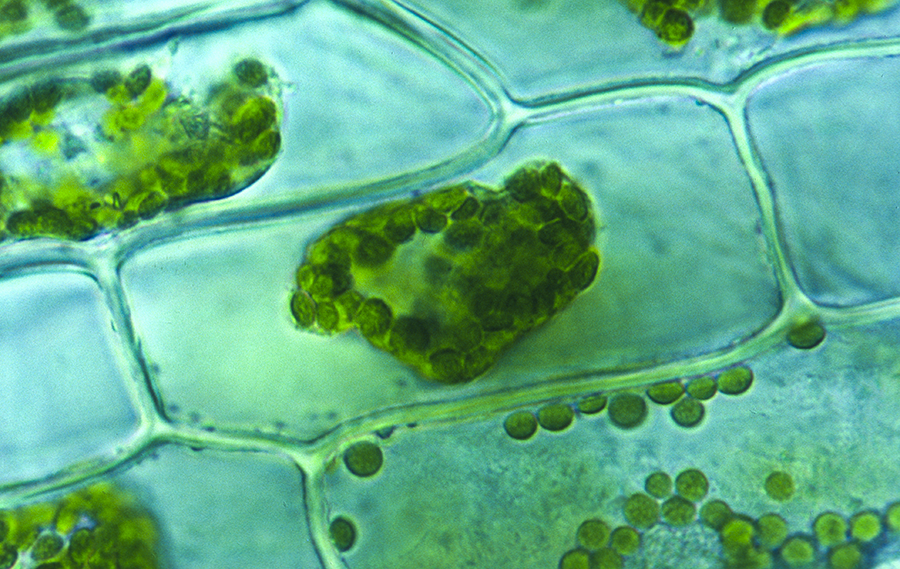

Plastikten üretilen monomerler çok sayıda ham petrol, doğal gaz ve selüloz gibi organik maddelerden elde edilir

The cellulose molecule found in the cell walls of plants can be used to produce seamless, soluble plastic.

Which Materials Contain Plastic?

Many items we use in our daily lives contain plastic. For example, water bottles, diapers, garbage bags, furniture, medical devices, wrapping paper, televisions, computers, phones, first aid tape, straws, toys and many other items contain plastic.

One of the most common areas where plastics are used is packaging.

How to Recycle Plastic?

Plastics are recycled through two main mechanisms: mechanical and chemical recycling

How Does Mechanical Recycling Work?

In the mechanical recycling method, waste plastics are first collected from recycling bins and brought to recycling facilities. After other materials such as glass and metal found together with waste plastics are cleaned, the plastics are separated according to their types. Because each type of plastic is recycled with different methods according to its chemical composition.

After plastics are separated according to their type, they are washed. During the washing phase, labels and food waste on the plastics are cleaned. The washed plastics are then crushed in crushing machines, reduced in size and dried.

shredded plastics

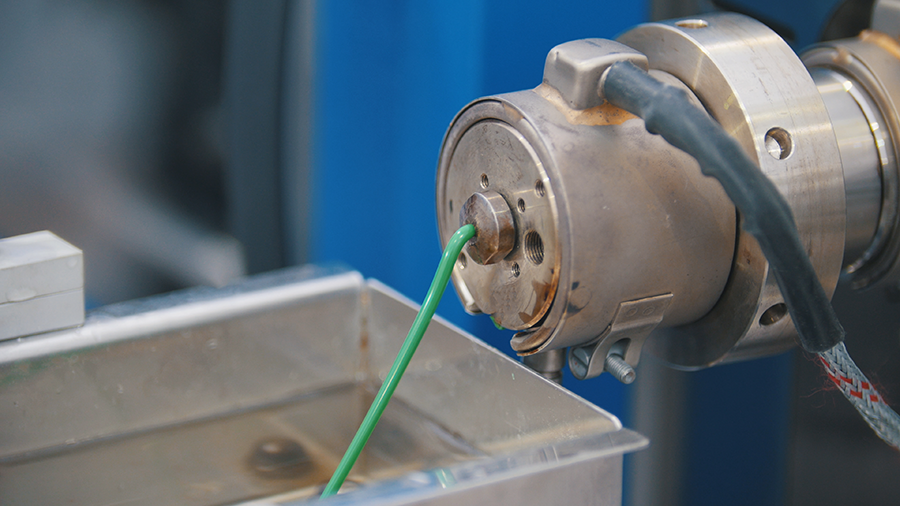

The dried plastic pieces are heated and melted in machines called extrusion machines. The molten plastic is shaped with different shaped tips at the end of the machine. The semi-fluid plastic coming out of the machine is cooled and completely solidified and cut to the desired dimensions and sized.

Plastic in the form of a cable coming out of an extrusion machine

Recycled plastics are sent to companies that produce plastic products and are used for the production of plastic materials again.

How Does Chemical Recycling Work?

Chemical recycling is an emerging technology used for plastics that are difficult to recycle or uneconomical to recycle mechanically. Three different methods are used in chemical recycling: purification, depolymerization and raw material recycling.

In the purification method, plastics are dissolved using appropriate solvents according to their types. In this way, plastics are purified from foreign materials and other wastes that cannot be dissolved in the solvent. Purified plastics are crystallized and separated from the solvent and made reusable. This method is mostly used for polyvinyl chloride (PVC), polystyrene (PS), polyethylene (PE) and polypropylene (PP).

Rope made of polypropylene

In the depolymerization method, the plastic to be recycled is separated into monomers or shorter polymer fragments called oligomers by the effect of solvents, chemicals and temperature.

In the raw material recycling method, pyrolysis, gasification or hydrothermal processing is used. In the pyrolysis process, plastic is exposed to high temperatures in an oxygen-free environment and its hydrocarbons are separated. At the end of this process, plastics are converted back to synthetic crude oil. In the gasification process, plastic is exposed to very high temperatures in an environment with limited oxygen and at the end of this process, the plastic is converted into gases such as hydrogen, carbon monoxide and methane. In the hydrothermal process, the plastic is reacted with hot pressurized water and at the end of this process, monomer and different chemical substances are obtained from the plastic.

What Can We Do Individually to Prevent Plastic Pollution?

According to research, less than 10% of plastics produced each year are recycled. This causes plastic pollution to increase. So what can we do individually to prevent plastic pollution from increasing?

- We can throw the plastic we use into the relevant recycling bin.

- We can use shopping bags instead of plastic bags for shopping.

- We can choose reusable bottles instead of single-use plastic bottles.

- We can use glass products instead of plastic.

- We can choose reusable or paper straws instead of disposable straws.

- We can choose natural fabrics such as cotton, wool or bamboo instead of synthetic fabrics.

Dictionary:

Katalizör: Substances that cause a reaction to occur more quickly but are not consumed during the reaction.

Sources:

- https://www.bpf.co.uk/plastipedia/sustainability/how-is-plastic-recycled-a-step-by-step-guide-to-recycling.aspx

- https://www.bpf.co.uk/plastipedia/chemical-recycling-101.aspx

- https://www.voanews.com/a/percent-of-plastic-worldwide-is-recycled-oecd-says-/6455012.html

- https://www.unep.org/interactives/beat-plastic-pollution/

- https://news.climate.columbia.edu/2018/05/11/can-fight-plastic-pollution/